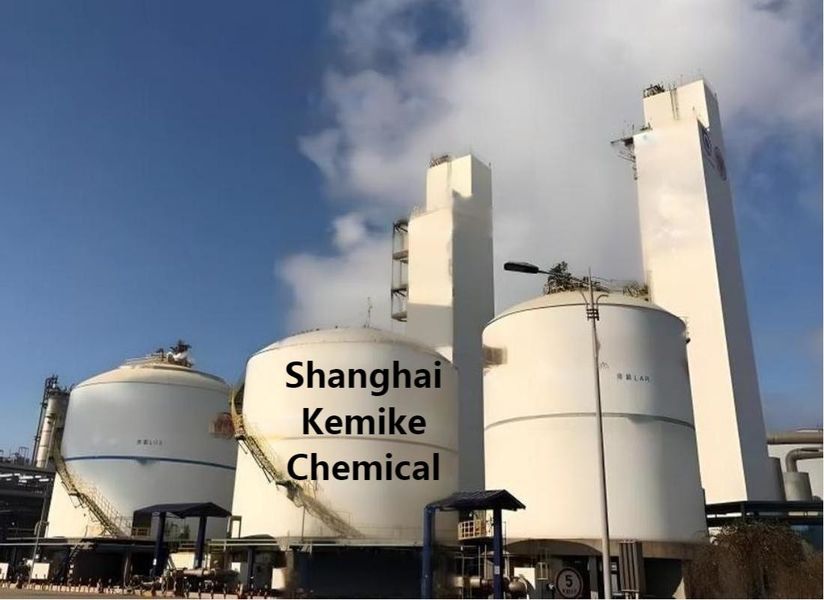

Shanghai Kemike Chemical Co.,Ltd

Fueling Innovation with Chemical Gases

Detail Information

Main Market:

North America

, South America

, Western Europe

, Eastern Europe

, Eastern Asia

, Southeast Asia

, Middle East

, Africa

, Oceania

, Worldwide

Business Type:

Manufacturer

, Distributor/Wholesaler

, Agent

, Exporter

, Trading Company

, Seller

Annual Sales:

1000000-5000000

Detail Description

We are a leading industrial gas manufacturer dedicated to providing high-quality gases and innovative solutions for various industries. We supply cylinder gas, electronic gas, etc ., and the gas holder, panel, valves and fittings and other equipment, parts and engineering services to our customers in China and worldwide; The products are involved in various industrial fields, such as semiconductor chip, solar cell, LED, TFT-LCD, optical fiber, glass, laser, medicine , etc., Our mission is to partner with our global customers to provide support, solutions and quality products that are innovative,reliable, and safe.

Our products mainly include: H2, O2, N2, Ar, CO2, propane, acetylene, helium, laser mixed gas, SiH4, Sih2cl2, SiHCL3, SiCL4, NH3, CF4, NF3, SF6, HCL, N2O, doping mixed gas (TMB, PH3, B2H6) and other electronic gases.

production line

Our factory serves as the heart of Industrial Gas Company, enabling us to meet the diverse needs of industries with high-quality industrial gases. With a strong focus on safety, quality control, and environmental responsibility, we strive to exceed customer expectations and drive innovation in the industrial gas industry.

We are proud of our facility and the dedicated team that operates within it. Should you have any further questions or require more information, please do not hesitate to contact us.

oem/odm

OEM and ODM are two common terms used in manufacturing and product development. Here's what they stand for and the difference between them:

- OEM (Original Equipment Manufacturer):

OEM refers to a company that designs and manufactures products based on the specifications and requirements provided by another company or brand. In this arrangement, the OEM company produces the products, often including branding and packaging, as per the specifications provided by the client company. The client company then sells the products under its own brand name. The OEM company acts as a silent partner, providing manufacturing capabilities and expertise while maintaining the client's brand identity.

Benefits of OEM:

a. Cost Savings: Outsourcing manufacturing to an OEM company can often result in cost savings for the client company, as they don't have to invest in manufacturing facilities, equipment, or labor.

b. Expertise and Efficiency: OEM companies specialize in manufacturing and have the necessary expertise, experience, and infrastructure to produce products efficiently and at scale.

c. Time Efficiency: By partnering with an OEM, the client company can focus on other aspects of their business, such as marketing, sales, and distribution, while the OEM takes care of the manufacturing process.

- ODM (Original Design Manufacturer):

ODM refers to a company that designs and manufactures products based on its own designs and specifications. ODM companies typically create their own product designs, often with the flexibility to customize them to some extent based on the requirements of different clients. ODM companies usually offer a range of product options for clients to choose from, and the client can select the desired design and make minor modifications, such as branding or packaging.

Benefits of ODM:

a. Design Expertise: ODM companies have in-house design teams that are experienced in creating innovative and market-ready product designs.

b. Customization: ODM companies provide a certain level of customization, allowing clients to add their branding elements or make minor modifications to suit their specific needs.

c. Faster Time to Market: By leveraging existing designs and production capabilities, ODM companies can significantly reduce the time required to bring a new product to market.

It's important to note that the terms OEM and ODM are often used interchangeably, and the distinction between them can vary in different industries and contexts. Some companies may offer both OEM and ODM services, providing a complete range of manufacturing and design options to their clients.

Ultimately, whether a company chooses OEM or ODM depends on their specific requirements, resources, and strategic goals.

R&D

Shanghai Kemike Chemical Co., Ltd focus on the exploration, development, and optimization of various chemical gases, our properties, applications, and production processes. This field of R&D plays a crucial role in advancing industries that rely on chemical gases, such as the manufacturing, energy, healthcare, electronics, and environmental sectors.

Here are some key aspects of chemical gas research and development:

-

Gas Analysis and Characterization:

Chemical gas R&D involves analyzing the properties, composition, and behavior of different gases. This includes studying their physical and chemical properties, stability, reactivity, toxicity, and environmental impact. Analytical techniques such as spectroscopy, chromatography, and mass spectrometry are commonly used to gain insights into gas composition and behavior.

-

Gas Synthesis and Production:

R&D efforts in chemical gases focus on developing and optimizing production methods for various gases. This may involve designing and improving chemical synthesis routes, exploring alternative raw materials, enhancing reaction efficiency, and developing novel catalytic processes. The goal is to achieve cost-effective and environmentally friendly gas production methods.

-

Gas Applications and Process Optimization:

Chemical gas R&D aims to identify new applications, as well as improve existing applications, for different gases. This can involve studying their interactions with materials, surfaces, and biological systems. R&D teams explore ways to optimize gas processes, including purification, separation, storage, and transportation, to enhance efficiency, performance, and safety.

-

Safety and Environmental Considerations:

R&D efforts in chemical gases also focus on understanding and mitigating potential safety hazards and environmental impacts associated with their production, handling, and usage. This includes studying toxicity, flammability, corrosiveness, and the development of safety protocols, storage guidelines, and waste management strategies.

-

Sustainable and Green Gas Solutions:

Given the increasing importance of sustainability, chemical gas R&D places emphasis on developing sustainable and green gas solutions. This includes exploring renewable sources for gas production, minimizing greenhouse gas emissions, reducing energy consumption during production processes, and promoting recycling and reuse of gases.

-

Collaboration and Regulation:

Chemical gas R&D often involves collaboration with industry partners, academic institutions, and regulatory bodies. Collaboration facilitates knowledge sharing, access to specialized expertise, and the development of common standards and safety guidelines. Regulatory compliance is crucial in chemical gas R&D to ensure the safe production, handling, and usage of gases.

-

Technological Advancements:

Rapid advancements in technology, such as artificial intelligence, big data analytics, and process modeling, play a significant role in chemical gas R&D. These technologies enable researchers to analyze complex data, simulate gas behavior, optimize processes, and accelerate the discovery and development of new gas-related applications.

Chemical gas research and development is essential for driving innovation, safety, and sustainability in industries that rely on chemical gases. By continually exploring new applications, improving production processes, and considering safety and environmental factors, R&D teams contribute to the advancement of these critical gases and their impact on various sectors.

![]()

![]()

![]()

![]()

![]()